LATHE WORKS

For metalworking of parts in body of rotation form: shafts, bushings, pulleys, gear rings, couplings, rings and other alike products, are used CNC lathe. They are carried out works:

- hole enlarging, drilling, hole reaming

- male and internal thread cutting

- grind out of grooves

- treatment of internal and outside tapered and cylindric surfaces

- facing, treatment of steps, formed surfaces

- cut off pieces.

- diameter of the parts up to 1250 mm

- length up to 2000 mm

- work material: ferrous metals, alloys of ferrous and non-ferrous metals of any marks, titanium and nickel alloys, plastic

- hardness of the processed materials up to 60 HRC

- working accuracy along X / Z axeses up to 0.01 / 0.01

- manufacture of threads of any profiles

- machining of parts in the 5-coordinate synchronously.

Example of machining of parts on lathes:

MILLING WORKS

For roughing, semifinishing and finishing metalworking of simple and curved surfaces of details from ferrous and non-ferrous metals, alloys and plastics are used milling machines with CNC.

For roughing, semifinishing and finishing metalworking of simple and curved surfaces of details from ferrous and non-ferrous metals, alloys and plastics are used milling machines with CNC.

Depending on the configuration of the miller and the type of manufactured products can be carried out end, face, peripheral, shaped and other types of milling. For example, for treatment of big surfaces is used face milling. For profiles – shaped milling.

Milling works with metals include production of different types of through and one-side grooves:

- grooves

- incisions

- pits

- windows

- pockets.

- width of parts up to 3000 mm

- height of the parts up to 2000 mm

- length of parts up to 4000 mm

- work material: ferrous metals, alloys of ferrous and non-ferrous metals of any marks, titanium alloys

- working accuracy of pieces along the axes X / Y / Z to 0.01 / 0.01 / 0.01

- milling of threaded holes.

- machining of parts in the 5-coordinate synchronously

- all machines are equipped with Renishaw system for fast measuring of details.

ESSENTIAL METALWORKING EQUIPMENT

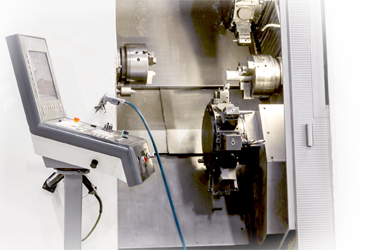

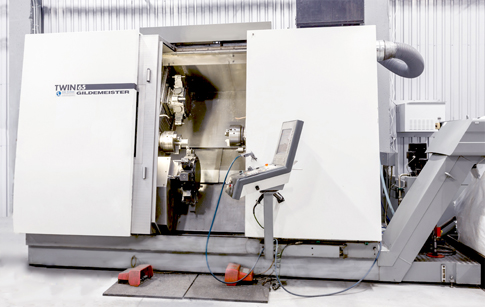

DUAL-SPINDLE TURN-MILLING MASHINE DMG GILDEMEISTER TWIN 65

Lathe with spindle- sub-spindle system that allows processing of metal products with a wide range of diameters. The modularity is appropriate for rods with diameter up to 65 mm. Equipped with delivery device of rods.

The increased size of the frame made it possible to place the CNC-controlled B-axis in the upper revolver zone. n combination with the Y axis it allows processing of work-parts of complex awkward shape, form angular holes and warped surfaces.

MILLING FIVE-AXIS COMPLEX MIKRON UCP 600

Compact constructed automatized automated complex for high efficiency concurrent milling on 5 axis.

Equipped with torque rotating-tilting table, variety of peripheral devices which allow easily change the tools, clean accumulated chips and metal-working oil. It can work a wide range of parts from hard-to-machine, superalloyed, super-strong materials.

MILLING FIVE-AXIS COMPLEX DMU 125, 70, 50

Universal machine with the possibility of concurrent milling on 5 axis.

Equipped with electronic balancing sensor, rotary table, and tank of 600 liters for metal-working oil. It has a unique construction with the best access of the cutting tools to the part that allows achieving high performance in processing.

TURN-MILLING MASHINE GMX 300 LINEAR AND GMX 200 LINEAR

The high-tech center for 6-sided complete 5-axis machining. It is used for large-series and small-lot production of parts of complex configuration.

Construction the straight drive, cruciform sledges with the axes Y and B and highly dynamic turning and milling spindle allows making turn-works and milling functions into one system.

High-revving, synchronous angle drive of tools, integrated spindle motors, programmable rest device and bar feeding device with the diameter up to 90 mm allow maximally optimizing and accelerating the process of manufacturing of parts. Copious supply of tools and the possibility of adjustment concurrently with the main production processes make the manufacture of small lots cost-effective.

MILLING 4-AXIS COMPLEX DMU 60H AND DMU 60H LINEAR

Universal horizontal mill with the possibility of milling of details with the rotation of pallets.

Equipped with electronic balancing sensor, rotary table, and tank of 600 liters for metal-working oil with self-contained cold store. It has a unique construction with the best access to the part which allows achieving high precision in lot and large-lot production. This machine equipped with the function of through-the-spindle coolant supply which adapt the tool life and improve quality of processing of the parts.