In July of 2016 we activate at SenV Group unique line for metal impregnation of the company ULTRASEAL

What is it for?

Vacuum impregnation by the sealing materials – cost effective solution of the problem of porosity of cast metal products.

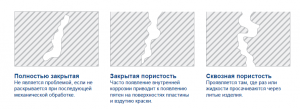

A lot of metals, during the transformation from liquid to solid stage, are subjected for formation of porosity. Voids and holes which are foming in the material, are invisible by the unaided eye, but effect on the working abilities of the details. Depends on pores’ comfiguration, it can be passed through them gas or fluid body, which can lead to failure of equipment and emergency situations.

Decision of porosity problem became using of saturant sealants – high stability, but flexible material, resistant to high temperatures, chemicals and oils. They fill any voids preventing leakage. Moreover, finished parts can be subjected to impregnation as it causes no changes of dimensions or contamination.

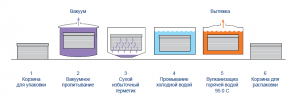

Technology, allows using of sealants to eliminate the microporosity, is vacuum impregnation of metal.